MINING AROUND STIRLING

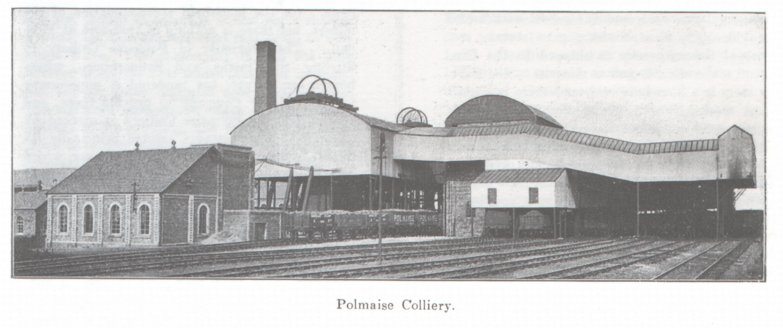

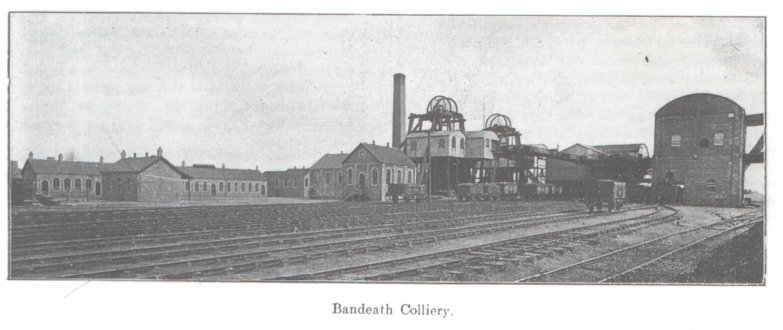

POLMAISE AND BANDEATH COLLIERIES

Extracted from

Industries of Stirling and

District

Originally published in the

Stirling Observer - 1908

Much has been written about, Stirling, historically and otherwise, and it is not an easy task, with the field already so well harvested, to find anything novel, and at the same time interesting, on which the pen might be employed. But that there is something yet left for the diligent gleaner we feel convinced, and that is the reason why we in this issue commence a series of articles on the local and district industries of Stirling. At first sight this may appear a waste of time, space, and energy, as the name and fame of the "City of the Rock" is usually not connected with industrial affairs, the historic past being mainly her portion. But that Stirling has like wise a present and a future in the arts of peace, now that the warlike past is dimmed, it will be our object to show in this series of articles The town itself may not be the centre of any industry of great extent, but there are numerous concerns of lesser size, and not a few of these are of an age, in the way of continuous, unbroken existence, that renders their history all the more interesting. To deal weekly with these and other industries, manufacturing and otherwise, is the object we have in view, and we have to thank the many cordial responses and promises of cooperation we have received from those we circularised as to our intention. It is possible, however, that someone has been forgotten, and if that is the case, we trust he will not think this is a slight, but will regard it as an un intentional overlook—which it is—and communicate with us in that spirit.

Coal mining is an old industry in Stirlingshire, and particularly in the eastern district, where it has been carried on for at least two hundred years in one form or another. The "black diamond" is known to exist all over the county, but until within a very recent period the nearest spot to the town of Stirling at which the coal was worked was Bannockburn. Round about that village of historic name there are yet to be seen old pit shafts, denoting the locality of mines, which have long since been abandoned, but this fact does not necessarily imply that the minerals have been wrought out. Far from it. There is yet plenty of coal in the district, and whilst new shafts have been sunk, old coal fields have been reopened, modern scientific appliances and machinery having made it possible to sink pits and work the minerals at a depth and under conditions which were beyond the reach of achievement half-a-century ago, and even less. No further back than 1843—only 65 years ago— contemporary history tells us that there were then no winding engines and cages in use in the collieries of Scotland, and women and also children of tender years were employed at underground work, carrying the coal from the "face" on their backs up steep slippery ladders to the pithead, or acting as "drawers," being yoked at the latter occupation in a kind of harness, after the manner of the ponies which are now utilised for that purpose, and which are also much better treated than the human beasts of burden were at the time we refer to. About a dozen years ago the development commenced of the coalfield in the Plean and Cowie district, and it has extended north and westwards, till we find it at the very door of Stirling, so to speak, whilst the miner, who had no place in local life half-a-dozen years ago, is now in his black face and working garb a familiar figure in the streets, as he passes between his place of abode in the burgh and his employment at the pits.

The agency responsible for this transformation is the enterprise of the well-known firm of coalmasters, Messrs Archibald Russell, Ltd., who have opened the Polmaise and Bandeath collieries in the Carse, a little to the south-east of Stirling, and as this is easily the largest industrial undertaking in the immediate vicinity of Stirling, we regard it as being the most suitable for opening the present series of articles on the subject. Polmaise Colliery is situated at Millhall, near Kersemill, about a mile and a quarter from the county town, and Bandeath is at Fallin, three miles away. Both collieries are in the parish 1.1' St Ninians, and on the estate of Major Alastair Murray, of Touchadam and Polmaise. The mineral fields comprise the following leaseholds— Polmaise, 2100 acres; Townlands, 600; BIackgrange and Westgrange, 400; Stewarthall, 270; Broadleys, 125; and Clayslaps, 30—a total area of 3525. Numerous bores put down at former times on Townlands and Stewarthall, along with seven diamond bores sunk by the present miners tenants on Polmaise, Blackgrange, and Westgrange, go to prove the existence of the seams of coal under practically the whole of the field. Blackgrange and Westgrange, it may be noted, are on the opposite side of the river Forth from the present coalfield being worked at Bandeath, but indeed there is coal all round Stirling—east, west, north, and south—and those versed in the matter inform us that in the near future the county town will be the centre of a much larger coal-mining community than we have at present. Indeed Stirlingshire, and particularly the Stirling part of it, is, in their opinion, destined to become one of the biggest coal-producing counties in the country. How this prospect will be relished by some people we have a shrewd notion, but within the last half-dozen years a great many persons in Stirling have learnt sense regarding mining and miners, and though hostile to their advent, would now be among the first to deplore their departure. Other communities have had to lament the working out of the coalfield in their vicinity, and the consequent loss of trade and employment caused by the closing of pits, and Stirling would in the same circumstances prove no exception to the rule. The first appearance of the miner is the worst of him, and like other people whose outward aspect may not be exceedingly attractive, he may, and does in the majority of cases improve on closer acquaintance. Despite his great affection—mistaken affection, if you will—for the Co-Operative Store, in which he deposits most of his earnings, the miner has always something left to spend elsewhere, and it will be admitted that he is no niggard in this respect. And free-handedness in this way makes up for other traits of character which are not so desirable.

But to return to the pioneers of the coal-mining development in our immediate neighbourhood, Messrs Archibald Russell, Ltd. This is an old firm, and it is interesting to learn that the founder of it was born within sight of the walls of Stirling Castle. The first Archibald Russell saw the light at Clackmannan, but moved westwards in early life, and became connected with the mining industry in Lanarkshire, in which county the interests of the firm are still largely concentrated. He began business in 1843—65 years ago—as a coalmaster at Cambuslang, and gradually extended it till he was the owner of half-a-dozen collieries. His son, Archibald Russell, got control of affairs in due time, and very largely developed them, being the owner of 21 pits—17 in Lanarkshire and 4 in Stirlingshire —at the time of his death. There was a third Archibald Russell, but he died, and in 1894 the business was, for family reasons, turned into a limited liability company, the leading members of it being four grandsons of the founder of the firm. The sinking of Nos. 1 and 2 pits, Polmaise Colliery, was commenced in December, 1902, and finished in June, 1904. Mr Tom Salmond, eldest son of the genial general manager of the Company, Mr Thomas Salmond, cut the first sod when sinking was started. This was a tedious and also costly operation, and it would stagger most people unacquainted with mining matters to learn the amount of money expended in this work?. The sinking was rendered very difficult owing to the surface strata, which was soft and troublesome, being composed in the following order of soil—yellow clay, very soft blue silt, peat, fine sand with water course sand and shells, red clay and stones, very soft red clay, sand, gravel, and boulders, and broken rock, the last being come upon 101 feet 6 inches from the surface. The pits were sunk through by means of a steel crib 24¼ feet long, 9½ feet wide, and 7 feet deep. The water got during the sinking was saltish, and was observed to be most abundant in quantity at the time of high tide in the river Forth, which is about 1 mile distant, indicating that the river really drained to some extent into the pit, which of course was at a lower level. The sinking of Nos. 3 and 4 pits at Bandeath was begun in August, 1904, and finished in April, 1906. The surface was of the same soft nature, although not so deep as that at Nos. 1 and 2 pits, being in this case 60 feet thick. The same method of sinking was adopted, a crib of like dimensions being used. The depth at which the coal is worked at Polmaise Colliery is 85 fathoms, 510 feet, and at 210 fathoms, 1260 feet, at Bandeath.

At Polmaise Colliery twelve seams of coal were passed through in the shafts, amounting in thickness to 23 feet 5 inches. The thicknesses of the seams which are at present being worked, and the depths at No. 1 pit, are as follows: — The Hartley seam, 2 feet at 291 feet deep; the Greenyard seam, 3 feet 3 inches at 372 feet; the Main seam, 3 feet 1 inch at 447 feet; and the Knott seam, 3 feet at 486 feet. At Bandeath the seams at present being worked, and the depths are as follows:—The Hirst seam, 2 feet 2 inches at 102 feet; the Hartley seam, 2 feet 4 inches at 1,008 feet; and the Knott seam, 2 feet 6 inches at 1,242 feet. The index limestone, 33 inches thick, was got at 786 feet. In. the sinking of the Bandeath pits the shafts passed through twenty seams of coal, over 1 foot in thickness, the total amounting to 32 feet 6 inches. In the pits at both collieries household coal, steam coal, and anthracite are found. The latter is a rare coal in Scotland, and the Polmaise and Bandeath variety is very good. It is a very hard, smokeless coal, and burns best with forced draught, such as is to be got in stoves, etc. Most of the anthracite is shipped to the Continent, and some also goes to America. The Hartley seam is a household coal, and there is a good home market for it, whilst the steam coal is largely used in industrial centres, and is also sent abroad. Needless to say, when referring to a firm of the high reputation of Messrs Archibald Russell, Ltd., everything in connection with the working of the collieries—both above and below ground—is of the most up-to-date description. It would serve no purpose to dwell at length on this phase of the enterprise, because the general reader would not understand the technical references that would have to be used, and it is sufficient to say that the machinery employed is of the finest pattern, and that every provision is made for the safety and comfort of the employees. Safety-lamps are in use throughout the pits. They are magnetically locked and electrically ignited : the underground appliance for relighting them being so constructed that it cannot be operated nor can a spark be produced unless the lamp is in position underneath an airtight closed-down lid. Two machines are fitted in the lamp-cabin: one for charging the accumulators, and the other for cleaning 100 lamps per hour. The pumping and ventilating apparatus are elaborate and most effective, and electricity is very largely used for motive, lighting, and other purposes. Preparing the coal by screening, washing, etc., are interesting processes that require to be seen to be understood, as have many other matters about a coal pit, where, alike in regard to human and mechanical equipment, some of the finest types of industrial development are to be seen.

Most collieries have in their near neighbour-hood a range or two of what are termed "colliers' rows," for the household accommodation of the miners, but there is nothing of that sort at Millhall. The proximity of Polmaise Colliery to Stirling, St Ninians, and Bannockburn, where houses can be got, has rendered it unnecessary for the Colliery Company to provide these, and the entrance to Polmaise Colliery is marked by thirty neat brick cottages, erected principally for the use of officials. At Bandeath, however, which is further away from Stirling and other residential centres, housing accommodation for a large number of the employees has been provided. There are twenty cottages for officials erected at the entrance to the colliery; eighty workmen's houses of the room-and-kitchen type, with all conveniences, have been built near it; and a hundred more are in course of erection. Water for domestic purposes is led in pipes for a. distance of 2 miles from the town mains; and, owing to the supply being scarce, storage tanks have been erected. The pit-water, pumped into tanks, is conveyed to the houses for flushing purposes. Between both collieries, when at full working strength, over 1200 hands are employed, and the wage bill is a large one. Just now there is an easing off, owing to the slackness in the coal trade, but with the return of brisk time the Polmaise and Bandeath collieries will undergo further development, giving more employment, and leading to the circulating of more money, and it will be the wish of everyone that the valuable enterprise introduced into the district by Messrs Archibald Russell, Ltd., should have a prosperous future before it.